Corrugated Iron

The main component of the scenery range is Eastwell Corrugated Iron products although the first AMBIS product was actually a colliery tub, produced for use on Coleorton No2.

A standard pack of corrugated iron contains 5 sheets over 5 inches long, making a strip over 24 inches depending upon the overlap per sheet.

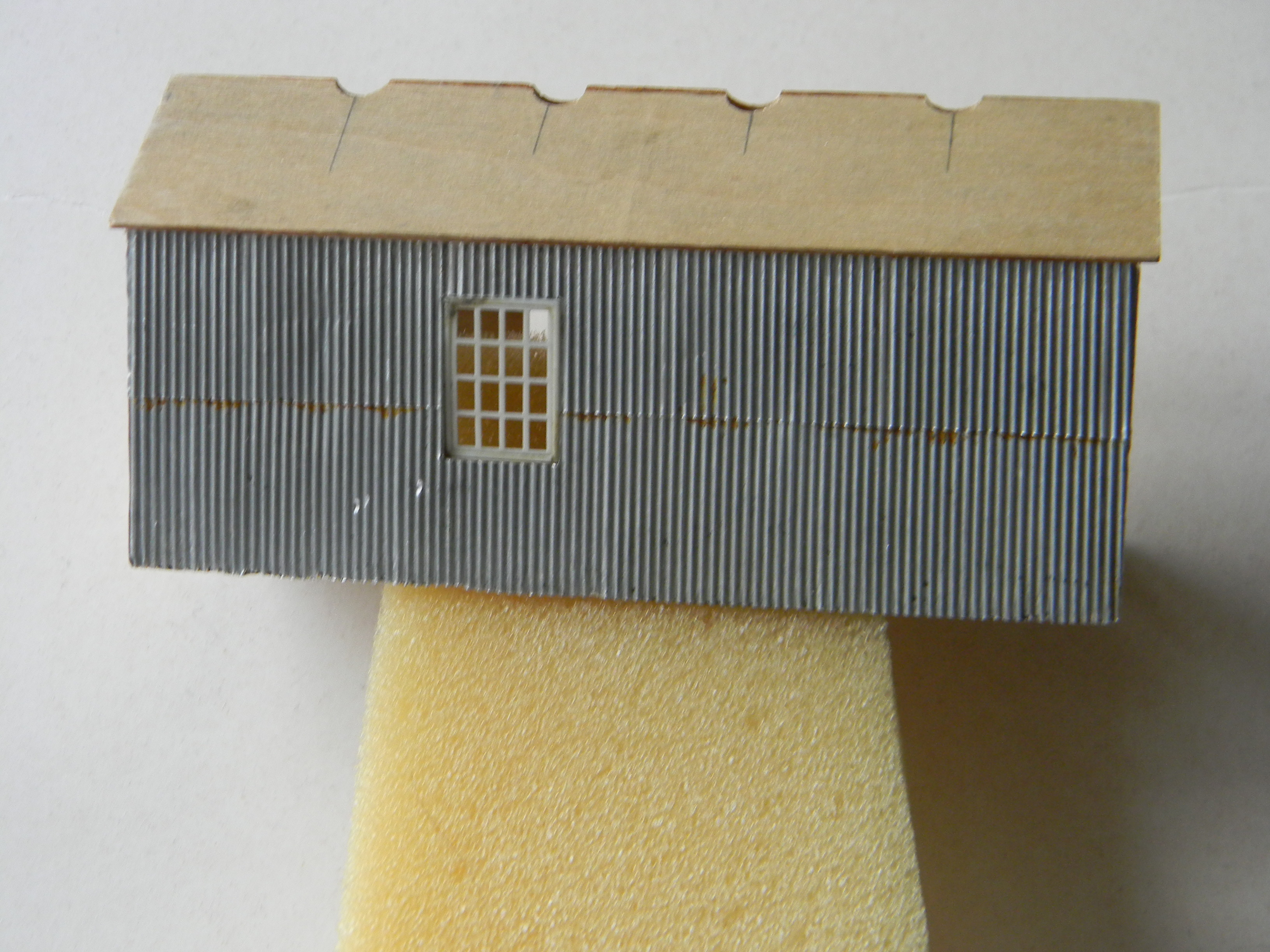

A small part finished shed in 2mm plywood clad in the domestic scale corrugated iron sheeting material to 4mm scale.

A solderable and more easily rust-able corrugated iron product a copper foil version is available.

When AMBIS took over the production and supply the range was extended into "O" gauge scales. To the origonal profile of abut 4 inches waveform (1.3mm) was added 2.1 and 3.5mm waveforms.

One of the main advantages of this product is it's thinness (about .002 inch) and its ability to be curved across the waveform. Whilst the small scale wave will cut like plastic sheet.

After many years of being able to produce the small profile corrugated iron up to 32mm high a new machine was finally put into service in 2013 making sheets up to 106mm high although we are not aware a corrugated sheet 26feet 6 inches long was ever produced. For details click here.

We could not rationalise the production of Eastwell corrugated iron that that scale using our production method but then we found a source of corrugated iron sheeting material in the USA for 2mm scale.and have marketed that product in our range.

Do not expect to cut or shape the larger waveforms without losing the waveform.

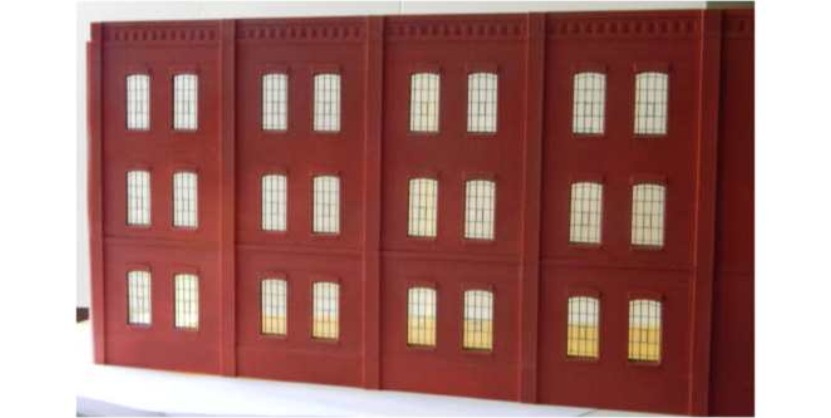

A first part of the factory window series were produced for "The Creamery Project" for the late Michael Warner. Other factory windows followed, some to modify proprietory buildings. The usual application of photo-etched windows would be in scratch built structures, but they can enhance and alter commercially available products.

Subsequent window patterns have been for railway station buildings, though they could equally well be used for other buildings. The list of station windows now available includes Ilkeston (MR), Kings Norton (MR), Evesham (MR), Higham Ferrers (MR), Water Orton (MR) and the larger stations on the Settle & Carlisle railway line (MR). We make no apology for focussing on Midland Railway architecture.

Two windows from Arthrington Gas Works were commission projects which filled a gap in the factory window range (BFW16 and BFW17).

The new factory windows introduced in 2013 which had tilting centre sections have been modelled with separate tilting panes so these made be assembled open, although we have no magic formula for glazing these windows when open. They will need very short 0.33 wire "pivots" to be added to the window etches. (BFW17 and BFW18).

For a list and diagrams of windows click here.

A third range being produced following a commission for a fence post pattern are other fence post designs. These will usually be ones that define railway land or are safety fences on high level railway lines.

We know of only a few signal boxes of a Midland Railway design, one at Hay on the Brecon & Merthyr Railway, 15ft by 10ft box, when the term "Station" was used on a signal box. In 1962 the "Hay Station" signal cabin had a Midland Style nameplate with wide spaced lettering on the front beneath the windows and an LMS style nameplate with closer spaced lettering under the eves on the left (steps) side of the box - we don't know if another name board adorned the other right side. The term "junction" was used even for direct siding access not just route junctions.

The splitter signal arms appear to be split equally aside a main post for route junctions while sidings or other operational line access may have used left or right brackets - a rule of thumb not backed by knowledge just observations.

Further research about the signal boxes has found some unique versions - as far as we know - such as Redditch South with two very wide windows to a six pane style. Then trying to make up an old 10ft square box has shown that these old versions had narrower windows in the door end where there was a wider support between the single window frames. It is not a lot of difference but it adds up to an distorted box. it appears that these narrower windows were used for the locking frame room windows, at least until stocks ran out and could have been replaced by the rectangular windows or in some cases pairs of four pane window frames - there is nothing new in recycling. These narrower widows are in the production process (November 2015).

A fold up etching for a Midland Ground Frame has been produced which includes additional windows for the less usual Midland signal cabins - the six pane "locking room" window and single or two pane windows used in platform/low height cabins. It is easier to assemble the ground frame inner shell if it is broken into three parts, the images shows overheated window mullions on the first "test etch". This is now being revised to make construction easier. Now we are working on other parts for signals - such as ladders the prototype etch is illustrated.

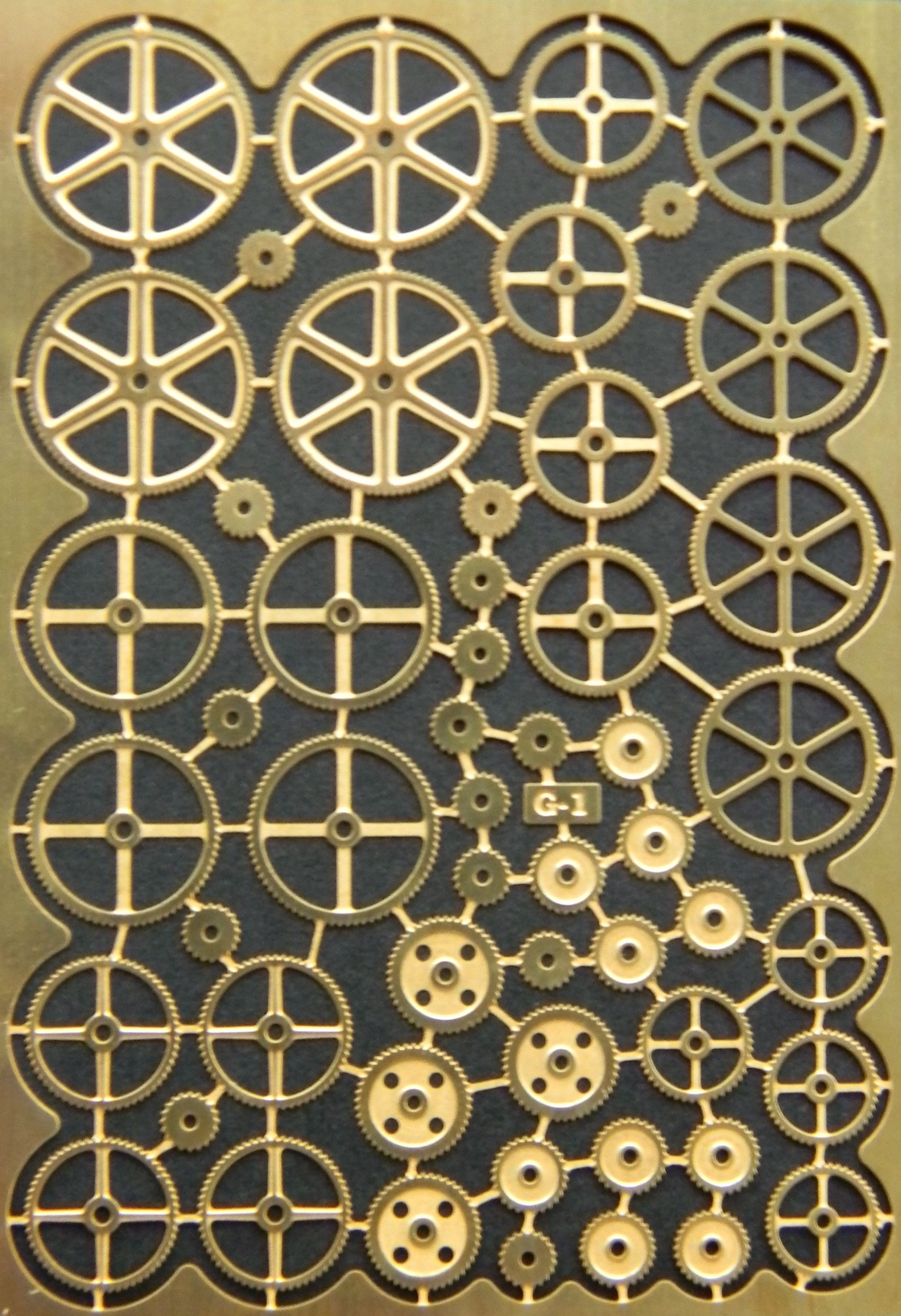

Following the successful production of signal wire pulleys we went one step further to etch a selection of gear wheels such as could be found on cranes. Each gear should be made from a number of layers as to finely etch gear teeth a .010 material has been used, equal to 3/4" thickness. But as castings gears can be several inches thick so we expect each spur gear to be made from two to perhaps 4 layers. It is not intended these gears should be made to work, though no doubt someone will try to make them operational. The images shown are the test etches, production items will be slightly different.

For more gears details click here

For more gears details click here

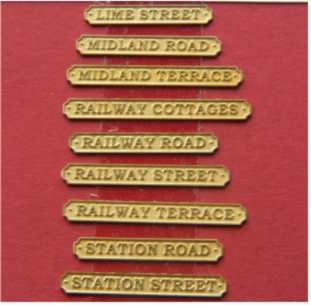

To supplement the locomotive name plates series a range of street name plates has been produced. These are available in fifteen themes with one plate of each name per set of 9 or 10 name plates.

Shown is the railway theme set.

We can also supply custom name boards with a coloured finish.

As a further offshoot we have also produced a series of real and imaginary signal box name boards in the Midland Railway Style, these too can be custom made.

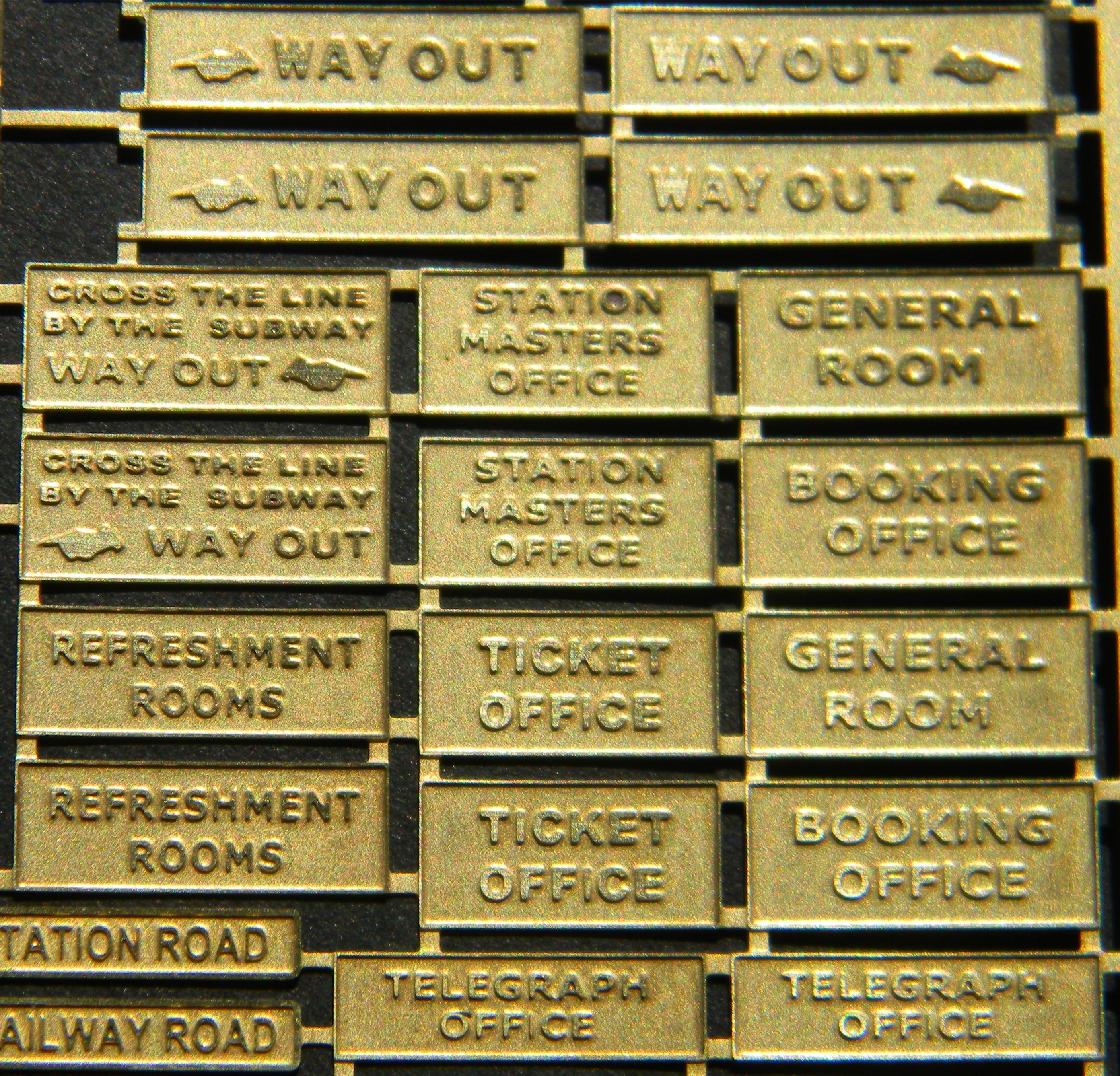

A small range of Victorian station platform signs were introduced to compliment the station windows and door ranges.

A list of all etched nameplates is available - click here.

A list of all etched nameplates is available - click here.

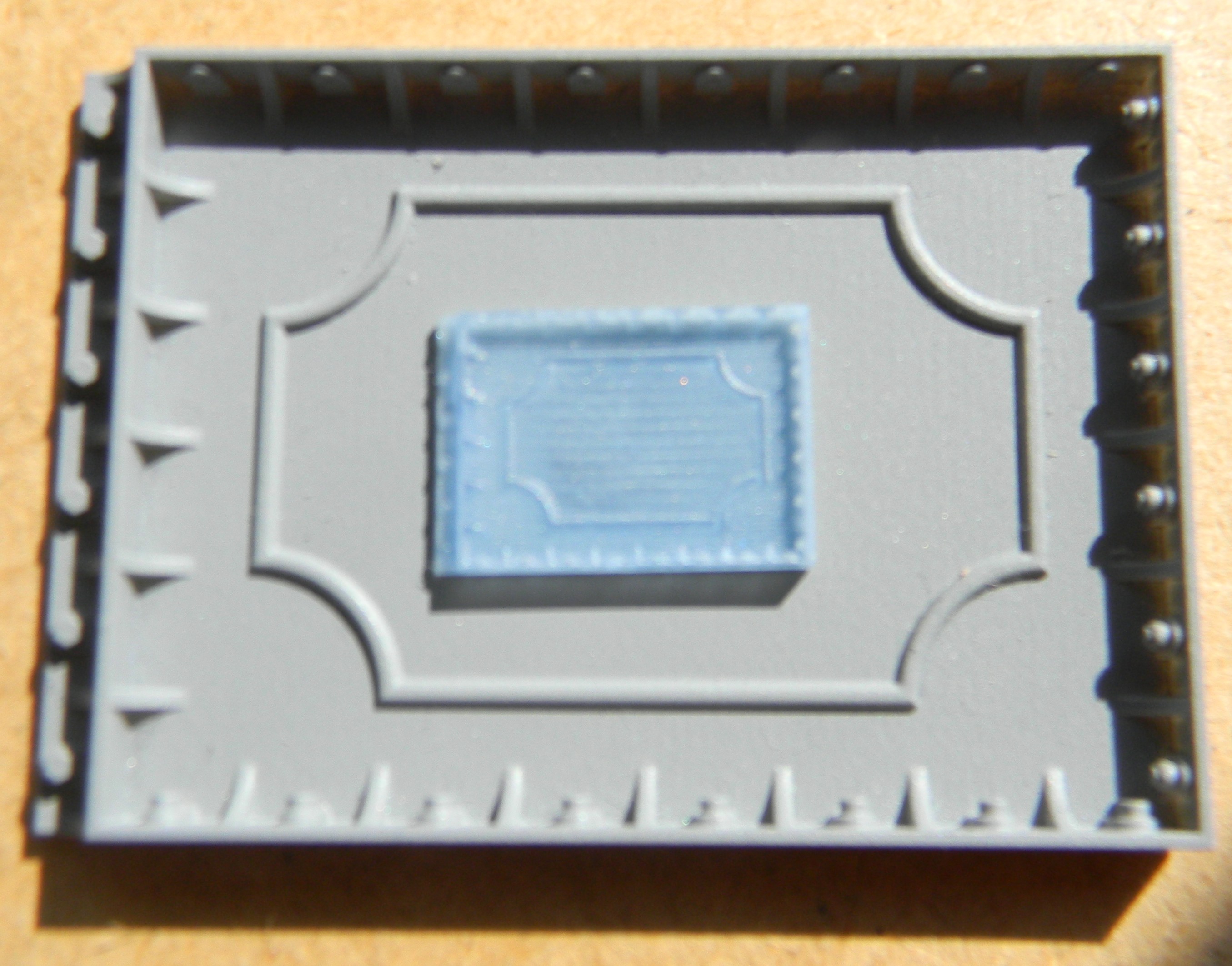

We have been investigating the use of 3D printing to produce items that are not particularly successful in sheet metal.

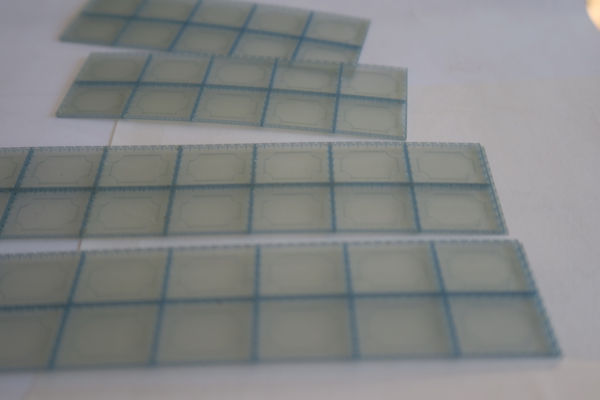

One project is the standard Midland Railway water tank panel. 4 feet by 3 feet in size - 16 by 12mm in a model. A trail version of a single panel version is illustrated - we have decided to make each side of a tank in one piece. The large panel is three times 1:76.2 scale, the smaller panel is to scale. The first production panel is also shown made from acrylic. It would be readily possible to produce 7mm@1 foot scale versions if required.

The next projects involve sleepers and then a truss girder bridge.

Some Bachmann DPM building modules improved by the application of our window etches.

The new opening windows this is BFW21 installed in a Bachmann DPM based building.

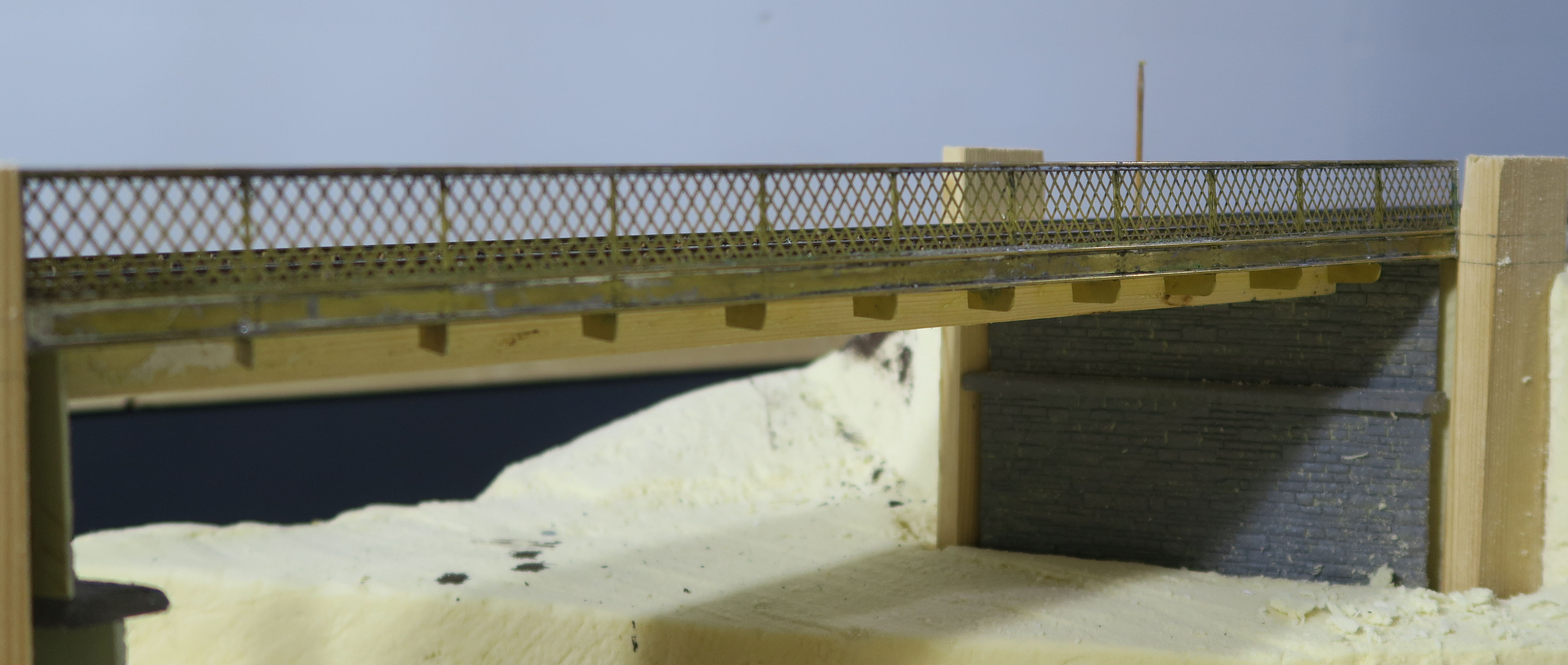

The first of a small series of bridge safety fences was produced in brass or phosphor bronze. The supporting structure is likely to be a 3D printed item.

This will be a limited run product as their use is likely to be somewhat limited.