Gallery

We now have a YouTube Channel were videos produced about our "Eyam Project" illustrate some of the product range. The list of these videos is as follows:

Episode One - the back story to the Eyam Project - first prepared for Virtual Scaleforum 2020

Episode Two - specific reference to the stretchers product - first prepared for Virtual Scaleforum North 2021

Episode Three - Back to Basics about wagon conversions - prepared for EMGS Virtual May Expo 2021

This page presents the products in use, either by the designer or customers.

Model Railway Operation

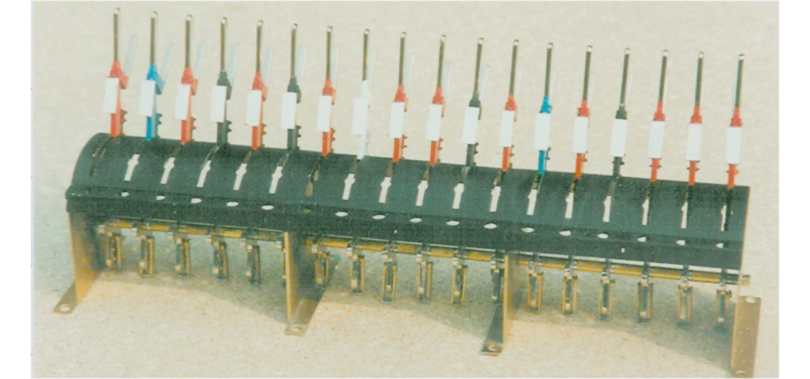

One of our first products was a mechanical lever frame, this is from a customer

It was built by David Yule from the Mk1 kit. He plated the (then) brass levers and cut out all the LED pocket holes in this 18 lever frame.

Coupling Rolling Stock

These parts were developed to fill a need and include variety to replicate the prototype variety.

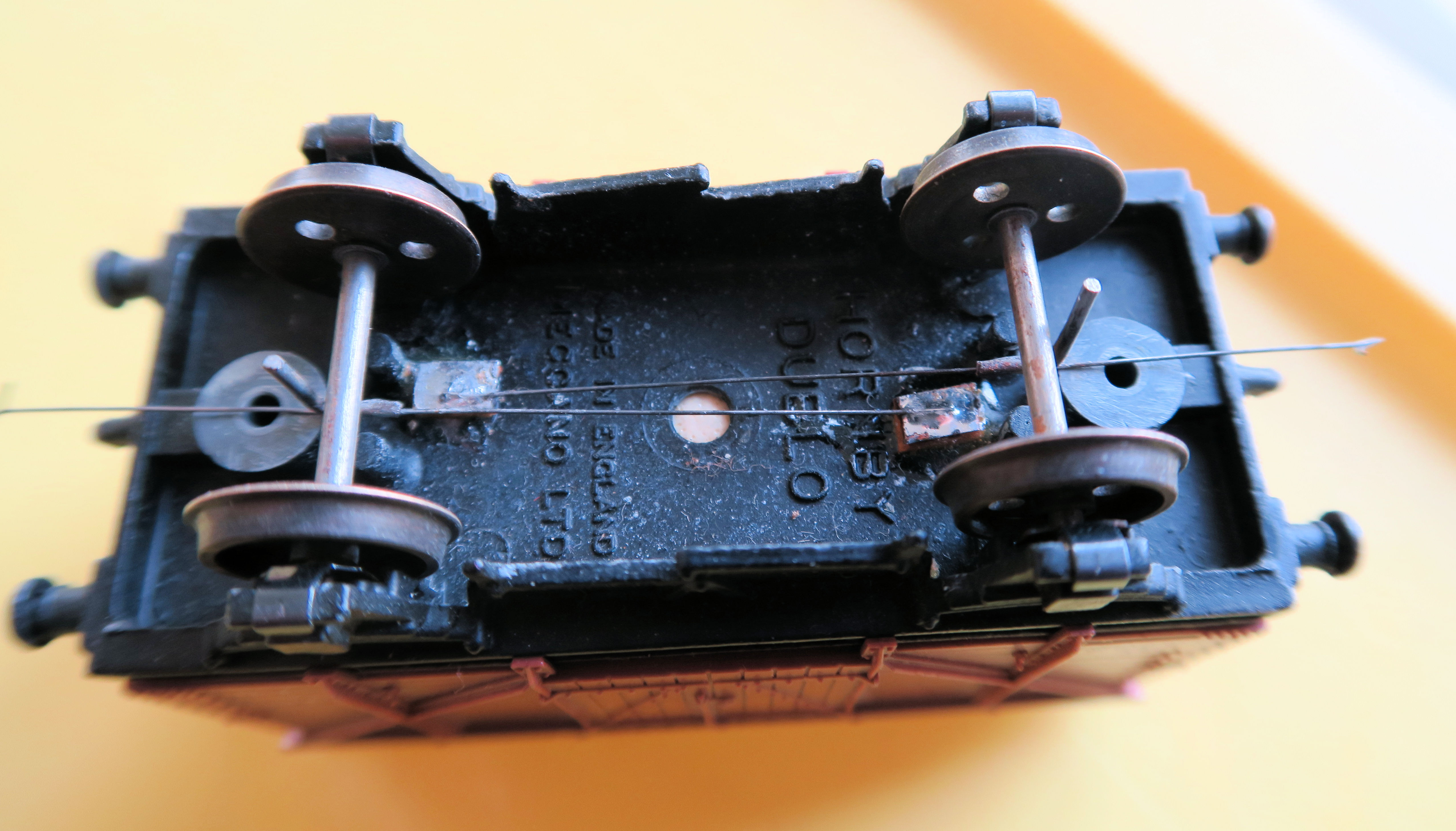

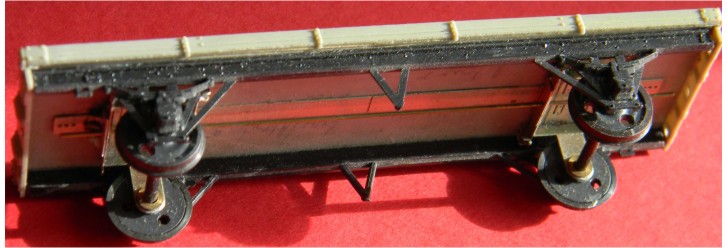

The Alex Jackson parts were inspired by my need and the invention of a customer to provide a solution for a common issue with the AJ coupling product. The photo is of a Hornby-Dublo wagon fitted with AJ couplings. Fortunately the old coupling boss was at the correct height for an AJ coupling.

Railway Trackwork Details

We set out to mass produce items for trackwork as there were no items available to meet our needs.

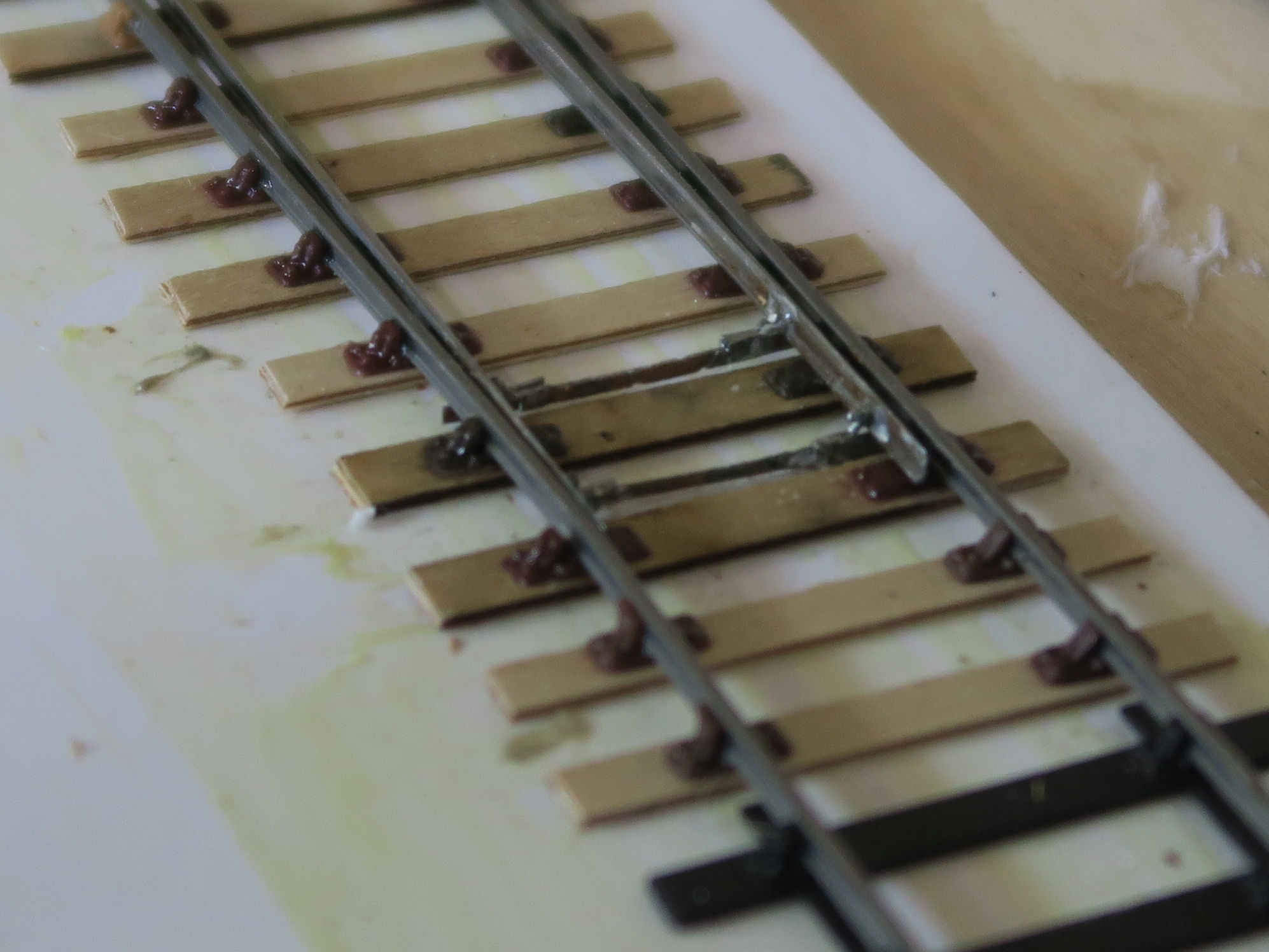

The Mk3 stretchers in situ, executed in nickel-silver - 4mm scale and C&L chairs, plywood sleepers.

The round stretchers again in 4mm scale using plywood sleepers and C&L components.

Rolling Stock Components

When parts fall off older wagons we wanted to replace them with more accurate items. This subsequently developed into a wide range or perhaps the more common parts that did not seem to be available for models.

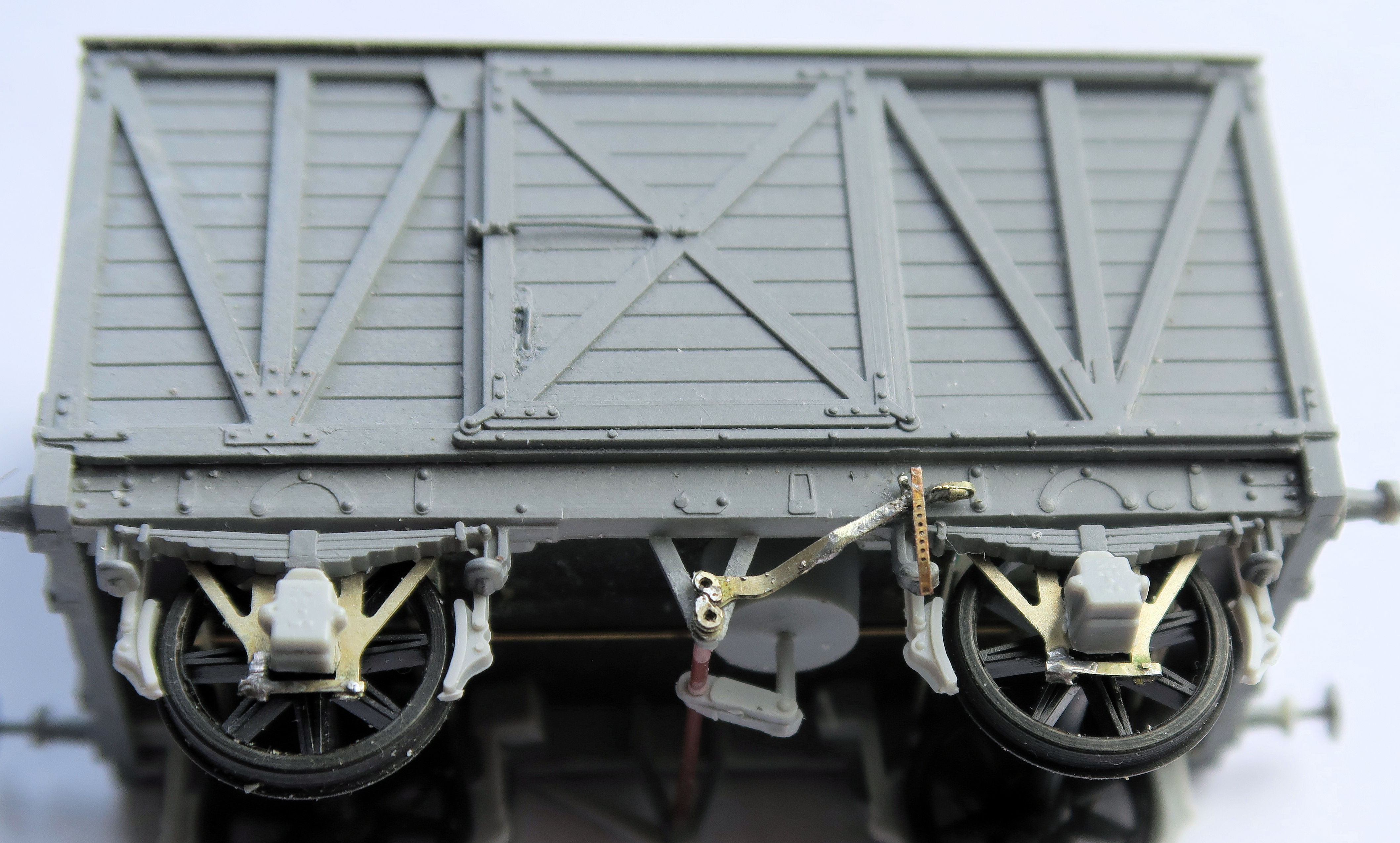

A refitted 7mm scale POW wagon with the Mk.1 brake lever guide.

Fitting on open ratchet brake lever and guide (GER wagons) to a plastic kit.

Morton clutch and lever guide to a Midland Railway fitted van.

A 4mm scale wagon fitted with working brake gear.

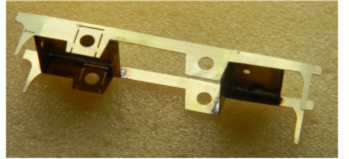

A similar set of parts for 7mm:1 foot scale.

A Long Low plastic kit with inside bearings being prepared for the AX3 axleguard etches.

Motive Power Components

Again these are items to fill gaps in what was available and what we thought would be useful.

An overlay for the Sharman Wheels Austerity profile wheels.

One of the test build chassis - for a MR 0-4-0ST.

Using the shackles - a customer ties down containers (not all parts are from AMBIS)

A customer who has used the 50550 coupling rods on a Hornby Austerity conversion to make a Hunslet 50550 class locomotive.

Scenery

These items grew from the Eastwell Corrugated Iron product. Initially they were for a coal mine layout, but the emphasis is now upon scenic items for the lineside. The windows range seems to keep expanding, more now due to commissions than to fill any immediate need.

A mixture of plastic kits modified by use of EIW corrugated iron sheeting.

A stone hopper clad in EIW corrugated iron.

In front of the weighbridge is an etched sign on a rail post.

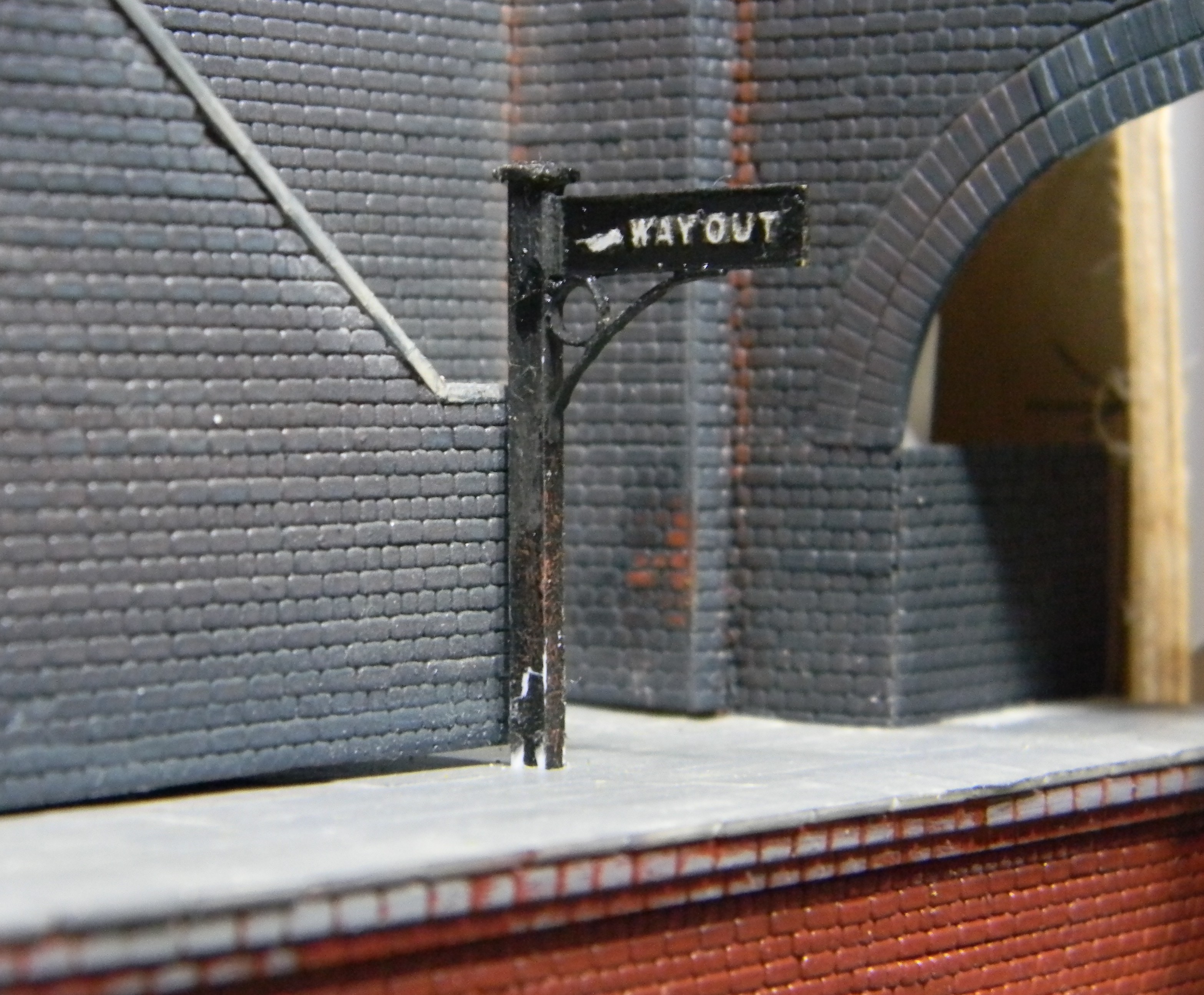

On the platform is a "WAY OUT" sign etched with added post and bracket.

The ticket office door has applied a small "Private" sign about 4mm long.

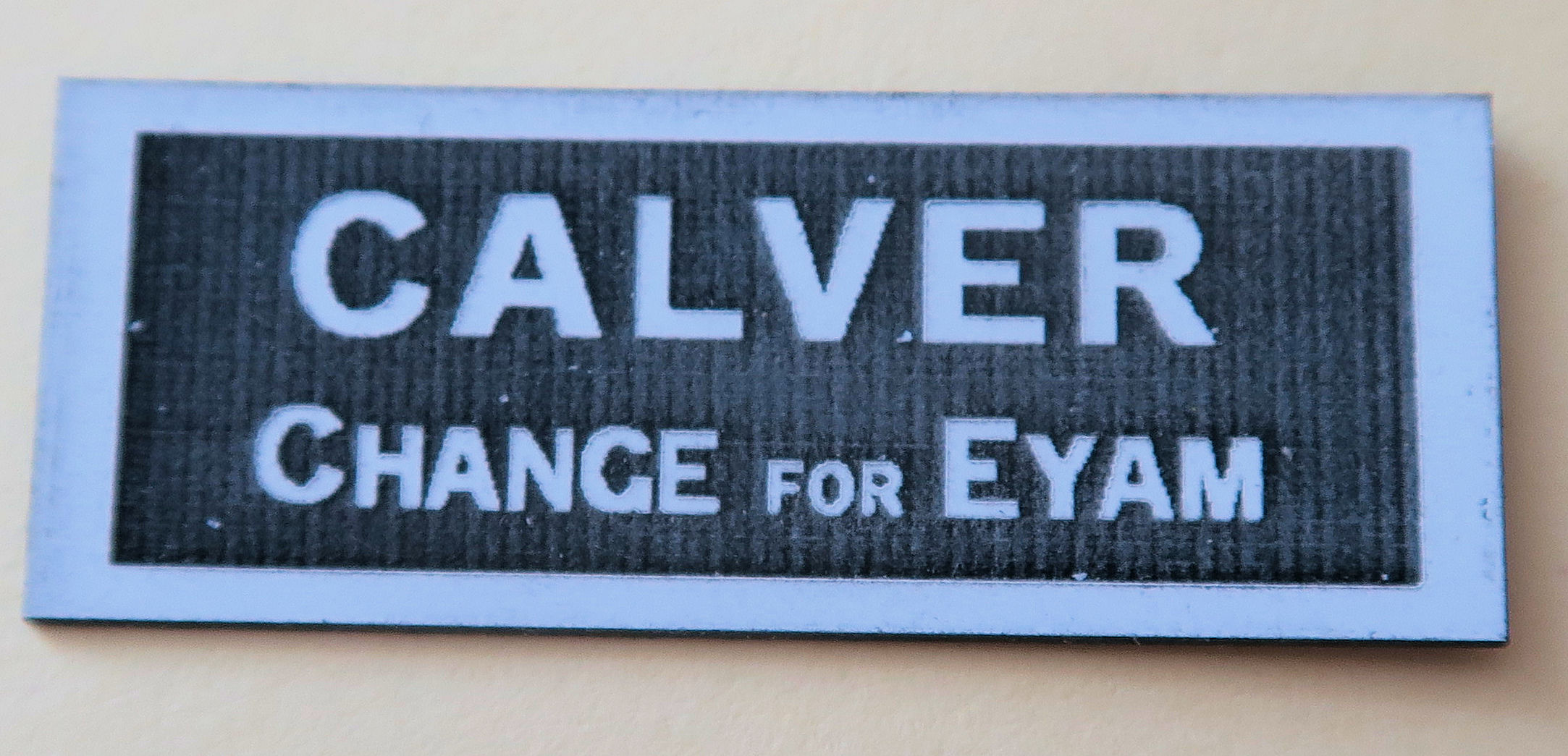

This station name board was engraved from a multi-coloured plastic sheet.

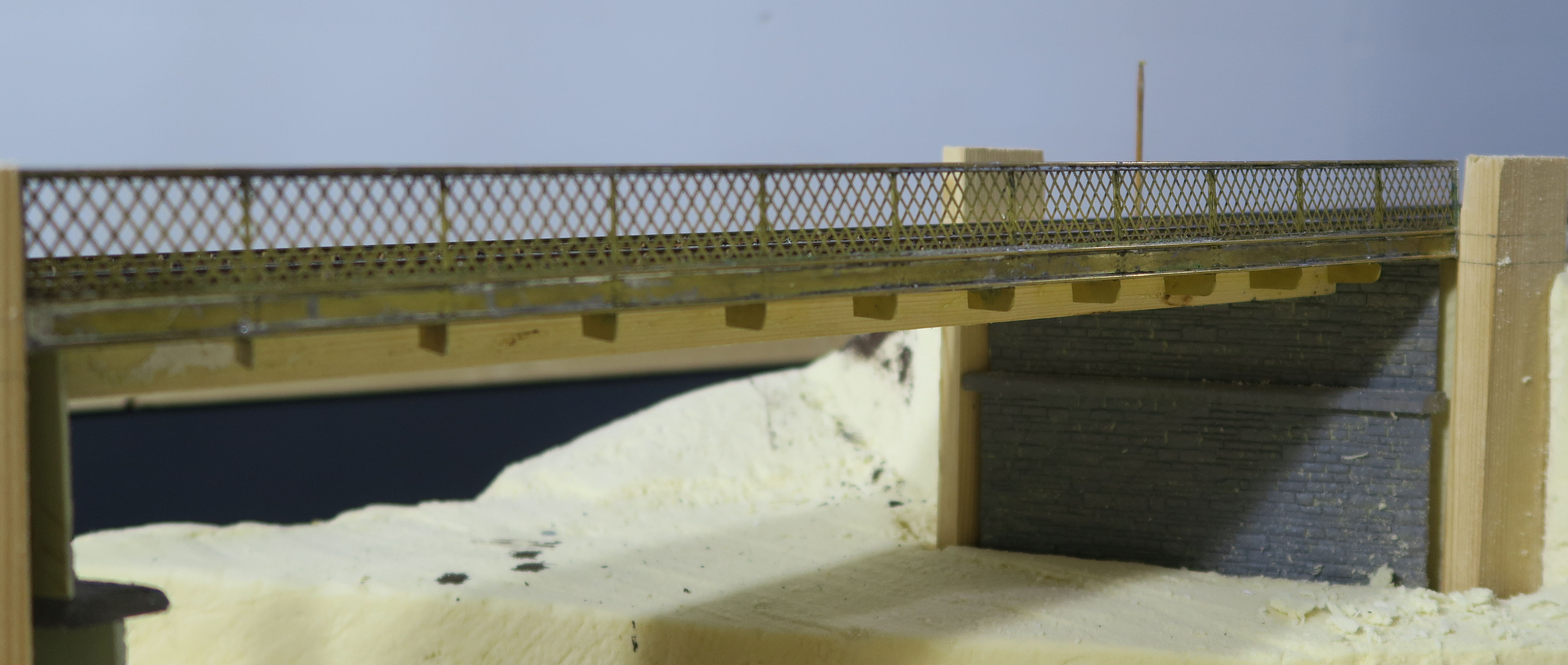

The beginnings of a truss girder underbridge the parapet is a two layer fold up etching with embellishments in half round wire.

We made a number of signal box windows which so far have been fitted to modified Melton Line kits. The roofs are loose for fitting interior details.

The name boards are etching the wider spacing is a Midland feature, the narrower spacing LMS.

This is my interpretation of the MR painting scheme (it could be wrong...). The other outside details are only going to be added once the surrounding scenery has been applied.

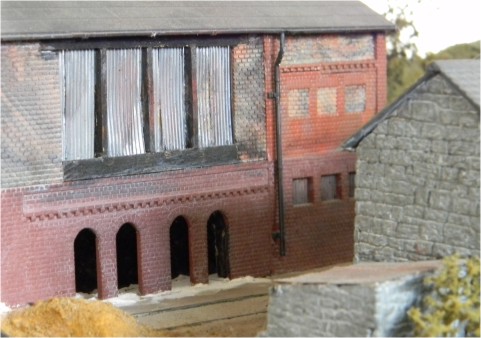

This is a large building largely made from DPM brick modules (from Bachmann), but generally fitted with etched windows.

Using the etched windows in buildings, based upon Haresfield (MR) and Stonehouse (MR)

The water tank house from Wills sheet material, laser cut corbels, plywood tank base and AMBIS windows and doors. The water tank is being installed - it is still waiting for its access ladder and service access platform.

The main station building is more or less finished uses etched windows and the lift gate etch, invisible behind the stairway.

The new girder bridges are being installed, many of the roadway details have yet to be finished and the trackwork ballasted.

Windows made for the Teviot Dale project in a building made by the customer.

Use of the station house (Dent version) windows by the customer.

Below - This photograph was taken at Scaleforum North 2018 - another application of the etched windows in Bachmann DPM modules.

A small chopper style coupling attached to a standard Bachmann wagon.

The CN2R coupling fitted to a Dundas coach kit